- Product Categories

- Industries

- About us

- Contact

Aluminium Casting & Processing

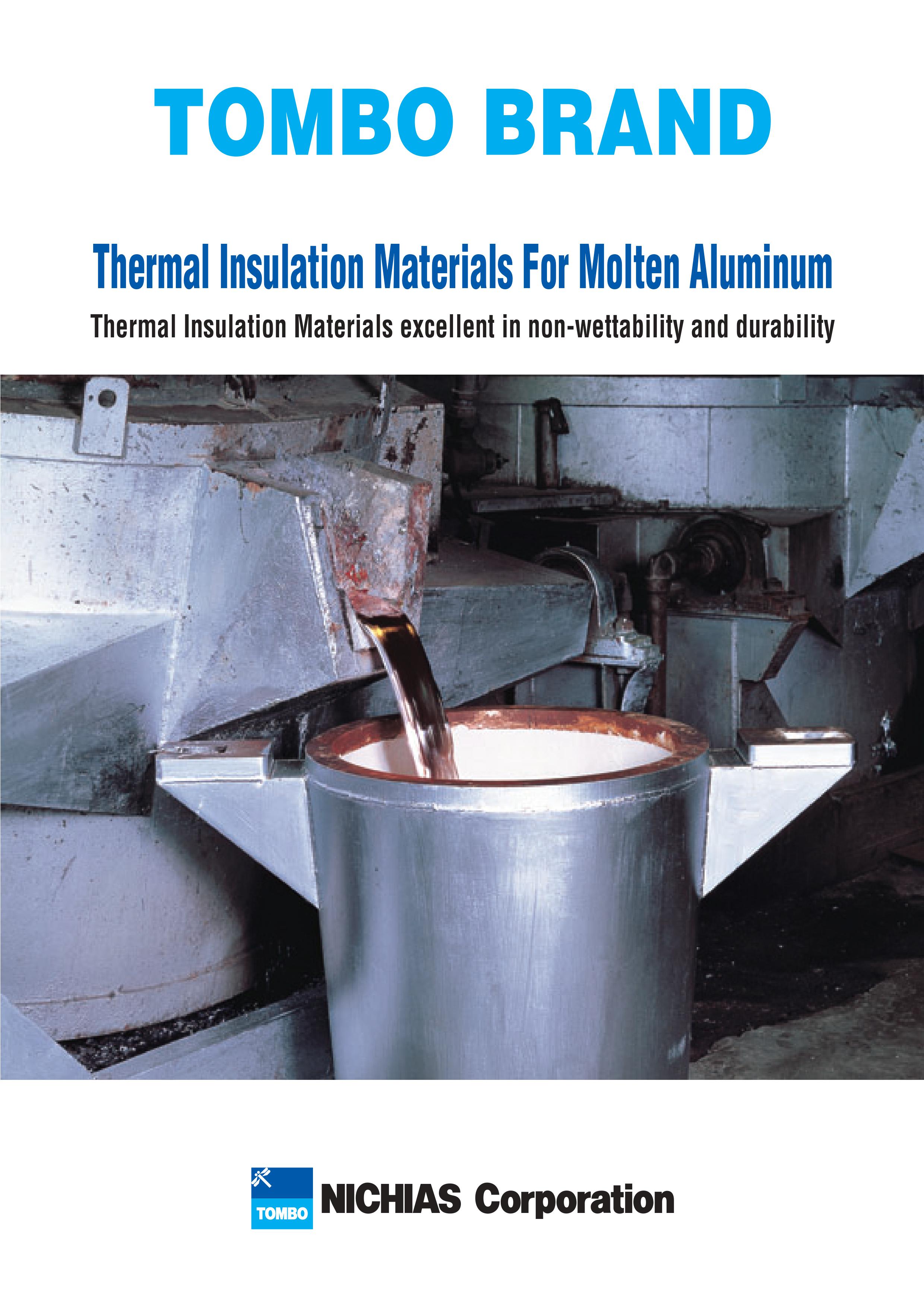

Aluminium is moulded and processed into products in a variety of forms through the processes from melting, transferring, holding to casting, etc. Insulation products manufactured by NICHIAS for molten aluminium feature non-wetting and low erosion performance, excellent thermal insulating properties and long service life. They are used as machined or cast components directly coming into contact with molten aluminium in every stage of processing. They contribute to secure high-quality aluminium products and consistency in quality as well as to improve productivity, efficiency of casting work and energy consumption.

Product solutions supplied by NICHIAS vary from cloth gaskets used after being treated with a rubber compound to seal distorted flanges and furnace cover flanges to which high seating stress cannot be applied, to moulded shapes for the molten aluminium vessels, to heat insulation boards (zonolite-based calcium silicate) used as launders, floats and other parts that come into direct contact with molten aluminium alloys, to calcium silicate thermal insulation materials which are able to withstand temperatures of up to 1000C and used as auxiliary insulation material for molten aluminium vessels, to high temperature packings used in furnace covers to seal the furnace.

Interactive Drawings

View our interactive drawing to see which NICHIAS products are used in Aluminium Casting & Processin…

Read more

Inorganic fiber products for ultrahigh-temperature use

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 5625 | FINEFLEX BIO™ Board | Board-form heat-insulation material | N/A |

| 5675 | FINEFLEX BIO™ CAST | Paste-form amorphous fire-resistant material | N/A |

Heat-resistant cloth

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 8250 | SILTEX™ | Silica cloth | N/A |

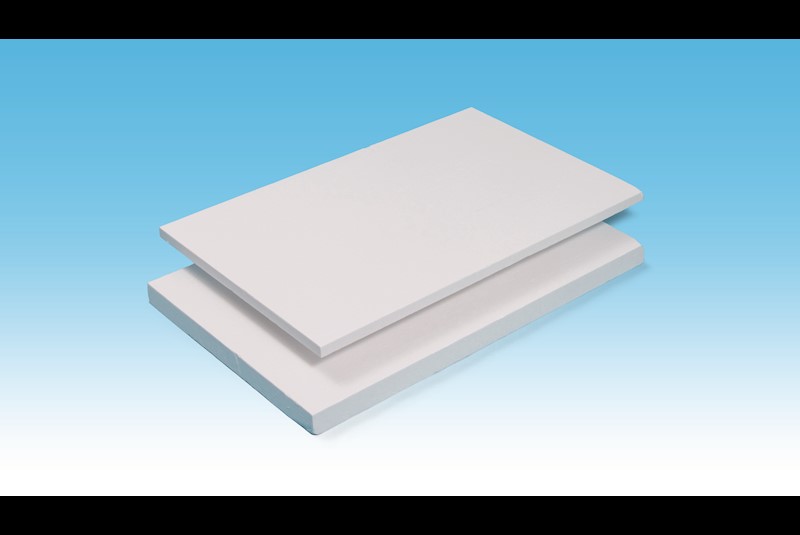

Low thermal conductivity heat-insulation materials exhibit high performance, thus saving energy and space for equipment.

They can be used in wide-ranging fields, such as industrial furnaces, combustors, and fuel cells.

Low thermal conductivity heat-insulation materials

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 4350-GH | ROSLIM™ Board GH | Board form heat-insulation material | N/A |

A heat expandable and fire resistant sheet made of a mixture of ceramic fiber, heat expandable and inorganic material with small amount of both organic and inorganic binders combined through the paper making proces.

General-purpose heat-insulation boards

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 6760-A | VERMOFLEX™ A | Heat-expandable and fire-resistant sheet | N/A |

Insulation products manufactured by NICHIAS for molten aluminum are excellent in non-wetting and low erosion performance, and durability. They are used as machined or cast components that come directly into contact with molten aluminum in every stage of processing. They contribute to improvement of product quality and yield, efficiency of casting work, and energy savings by reducing fuel consumption.

Castable thermal insulation material

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 4722-A | LUMICAST™ A | Ceramic fiber based fibrous castable | N/A |

* TOMBO is a registered trademark or trademark of NICHIAS Corporation.

* Name of products with "™" are trademarks of NICHIAS Corporation.

* Name of products with "™" are trademarks of NICHIAS Corporation.

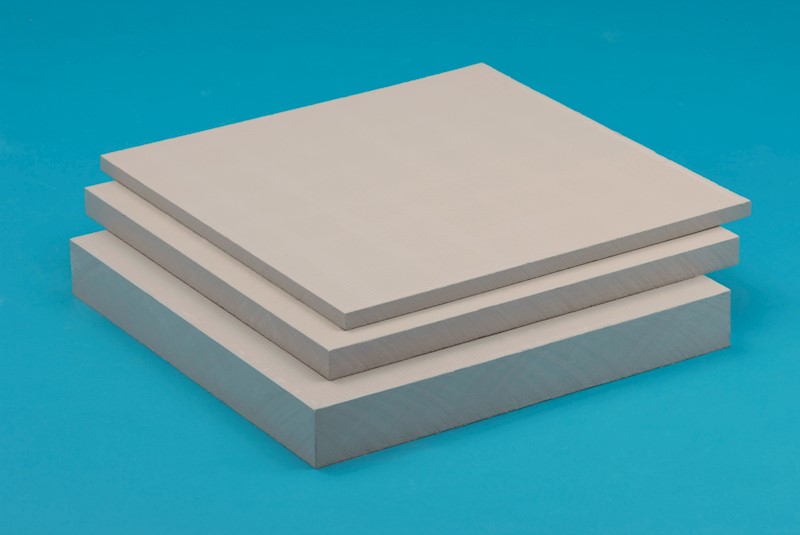

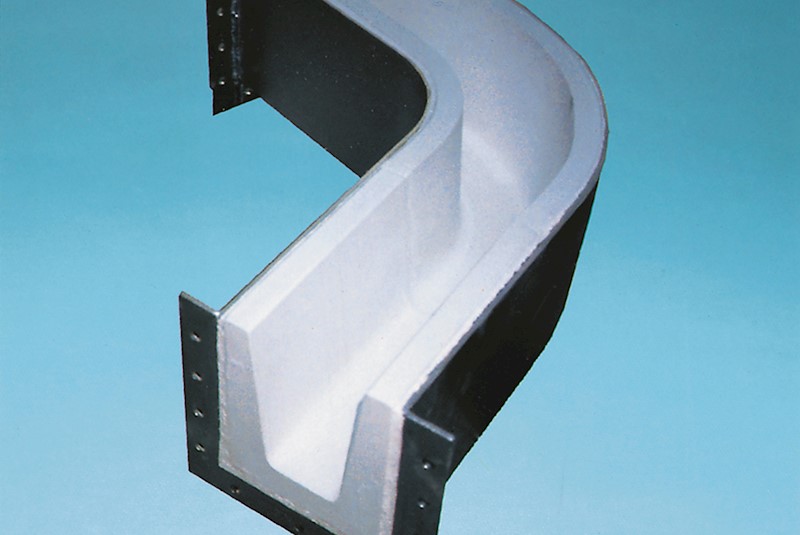

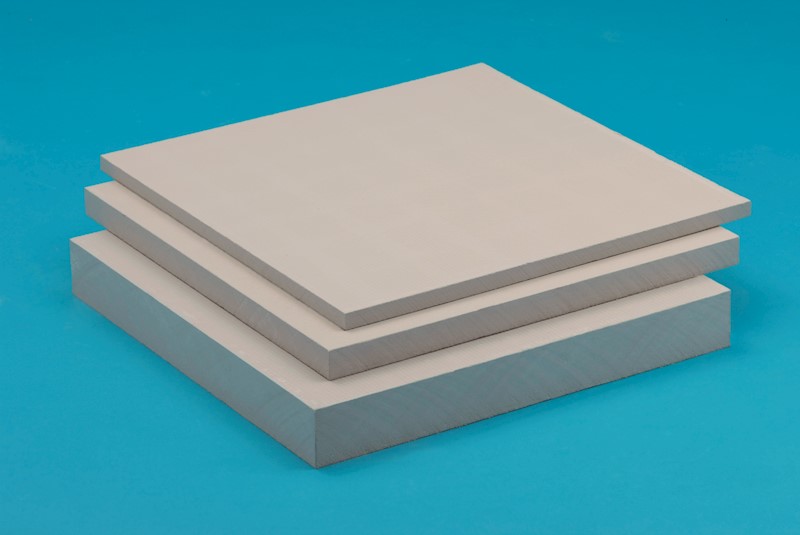

Insulation products manufactured by NICHIAS for molten aluminum are excellent in non-wetting and low erosion performance, and durability. They are used as machined or cast components that come directly into contact with molten aluminum in every stage of processing. They contribute to improvement of product quality and yield, efficiency of casting work, and energy savings by reducing fuel consumption.

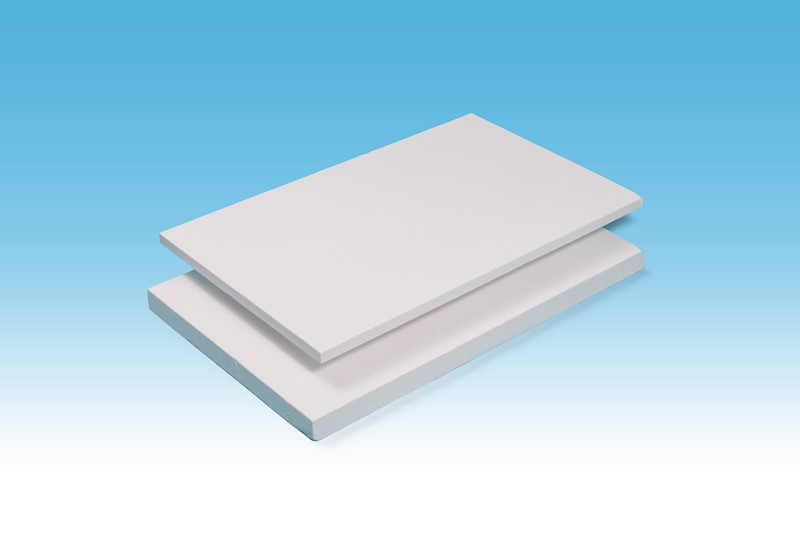

Thermal insulation materials for molten aluminum

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 4720 | LUMIBOARD™ | Board-form heat-insulation material for transfer, casting and holding | N/A |

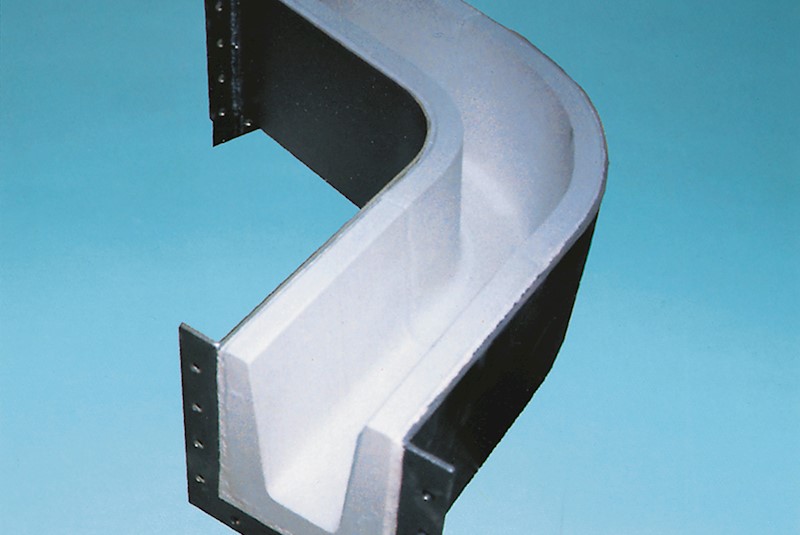

| 4723 | LUMISUL™ LD | Molded shapes for molten aluminum vessel | N/A |

| 4722-A | LUMICAST™ A | Ceramic fiber based fibrous castable | N/A |

* TOMBO is a registered trademark or trademark of NICHIAS Corporation.

* Name of products with "™" are trademarks of NICHIAS Corporation.

* Name of products with "™" are trademarks of NICHIAS Corporation.

Inorganic fiber products for ultrahigh-temperature use

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 5625 | FINEFLEX BIO™ Board | Board-form heat-insulation material | N/A |

| 5675 | FINEFLEX BIO™ CAST | Paste-form amorphous fire-resistant material | N/A |

Heat-resistant cloth

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 8250 | SILTEX™ | Silica cloth | N/A |

Low thermal conductivity heat-insulation materials exhibit high performance, thus saving energy and space for equipment.

They can be used in wide-ranging fields, such as industrial furnaces, combustors, and fuel cells.

Low thermal conductivity heat-insulation materials

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 4350-GH | ROSLIM™ Board GH | Board form heat-insulation material | N/A |

A heat expandable and fire resistant sheet made of a mixture of ceramic fiber, heat expandable and inorganic material with small amount of both organic and inorganic binders combined through the paper making proces.

General-purpose heat-insulation boards

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 6760-A | VERMOFLEX™ A | Heat-expandable and fire-resistant sheet | N/A |

Insulation products manufactured by NICHIAS for molten aluminum are excellent in non-wetting and low erosion performance, and durability. They are used as machined or cast components that come directly into contact with molten aluminum in every stage of processing. They contribute to improvement of product quality and yield, efficiency of casting work, and energy savings by reducing fuel consumption.

Thermal insulation materials for molten aluminum

| TOMBO No | Product Name | Description | Data Sheet |

|---|---|---|---|

| 4720 | LUMIBOARD™ | Board-form heat-insulation material for transfer, casting and holding | N/A |

| 4723 | LUMISUL™ LD | Molded shapes for molten aluminum vessel | N/A |

| 4722-A | LUMICAST™ A | Ceramic fiber based fibrous castable | N/A |

* TOMBO is a registered trademark or trademark of NICHIAS Corporation.

* Name of products with "™" are trademarks of NICHIAS Corporation.

* Name of products with "™" are trademarks of NICHIAS Corporation.

Aluminum Casting & Processing Downloads

Catalogs are property of NICHIAS Corporation. All rights reserved. Unauthorized duplication, appropriation, distribution, sale or other secondary use is prohibited.

NICHIAS is not liable for any loss or damage related to use of or inability to use these electronic files.

Content is current as of the date on the catalog's back cover.

Content may be changed without notice.

Please see the back cover for notices related to use of this catalog.

Other regulations and guidelines are found in the Terms of Use for this website.

NICHIAS is not liable for any loss or damage related to use of or inability to use these electronic files.

Content is current as of the date on the catalog's back cover.

Content may be changed without notice.

Please see the back cover for notices related to use of this catalog.

Other regulations and guidelines are found in the Terms of Use for this website.