- Product Categories

- Industries

- About us

- Contact

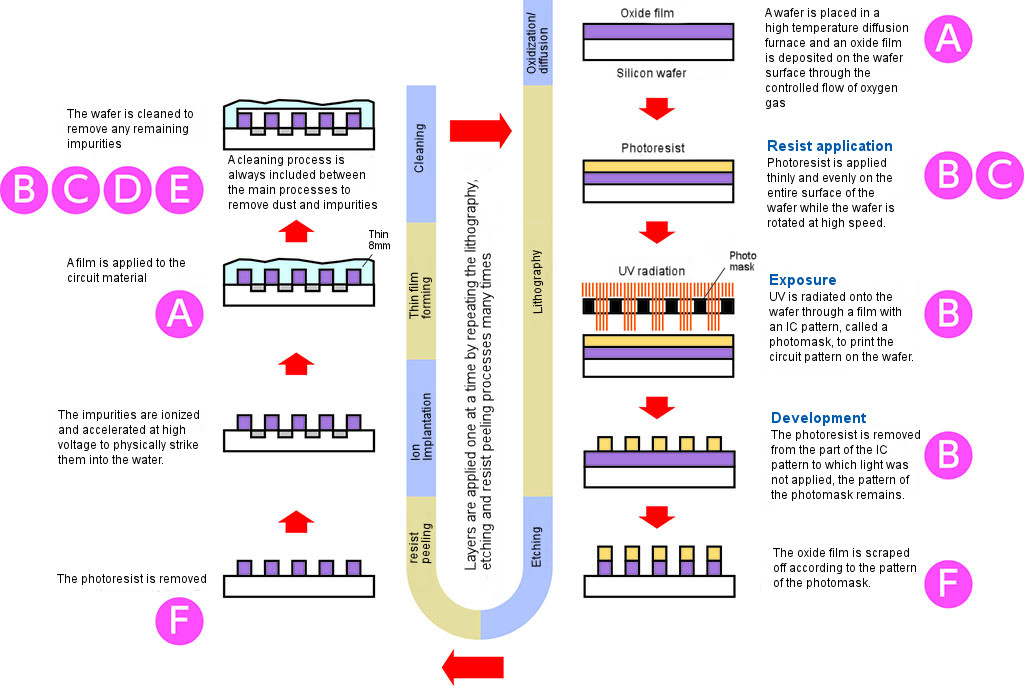

Semiconductor Product Process

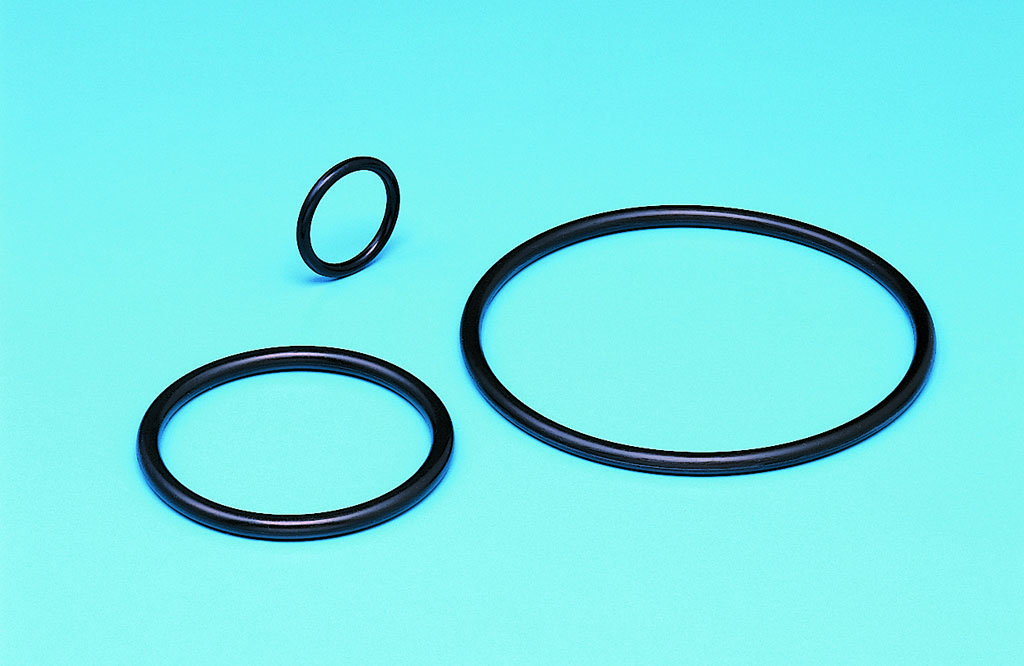

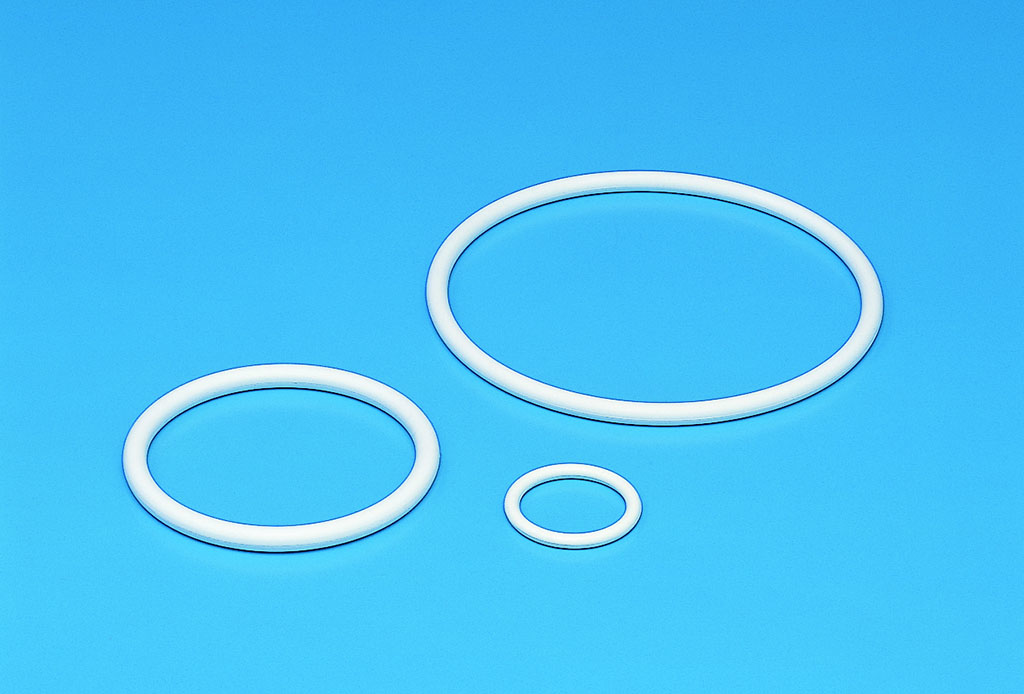

2670-BNX Rubber O-Ring BLAZER NEXT™

Rubber O-ring BLAZER NEXT is a sealing material used for semiconductor and FPD heat treatment equipment, piping and valves in various industrial fields. With excellent heat and chemical resistance as well as low gas emissions at high temperatures. It is used to seal oxygen gas inlet ports in diffusion furnaces and for wafers carrying inlet and outlet ports. It is also perfect for sealing heat treatment equipment used in processes such as oxidation, diffusion, ion implantation and thin foaming9003-PFA-HG NAFLON™ PFA-HG Tubing

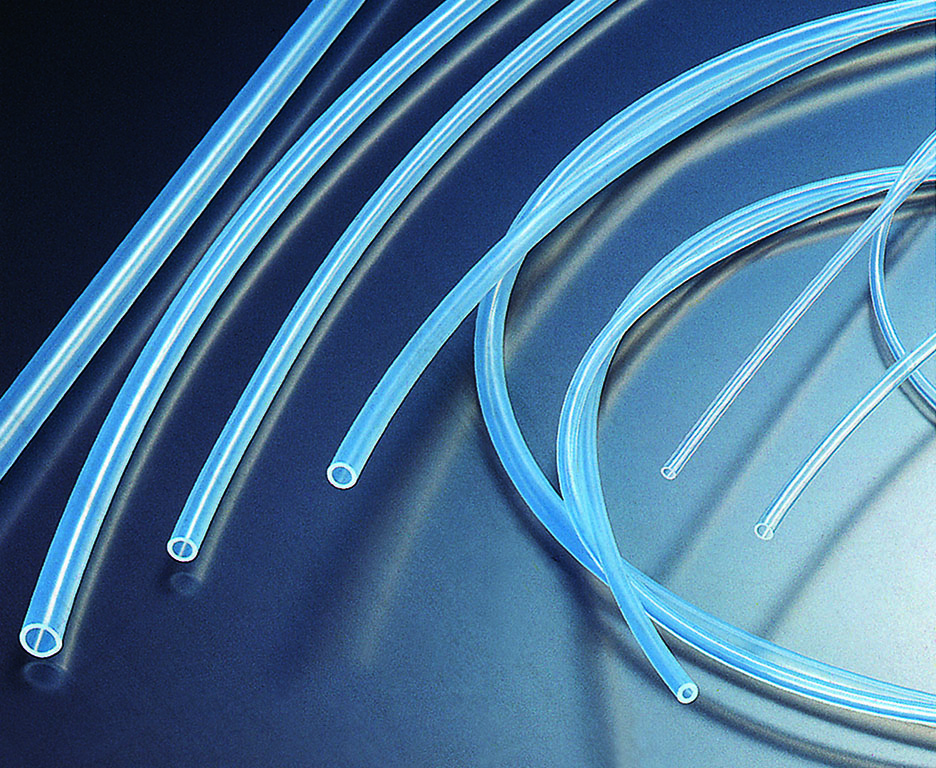

9003-NE NAFLON™ PFA-NE Tubing

PFA-HG tubes have excellent chemical and heat resistance. They also feature a high level of cleanliness due to the minimal generation of eluted ions, as well as a smooth inner surface that prevents build-up of chemical residue. PFA-NE tubes are HG tubes with the addition of a striped conductive layer around the circumference, providing antistatic properties on the tube outer surface.

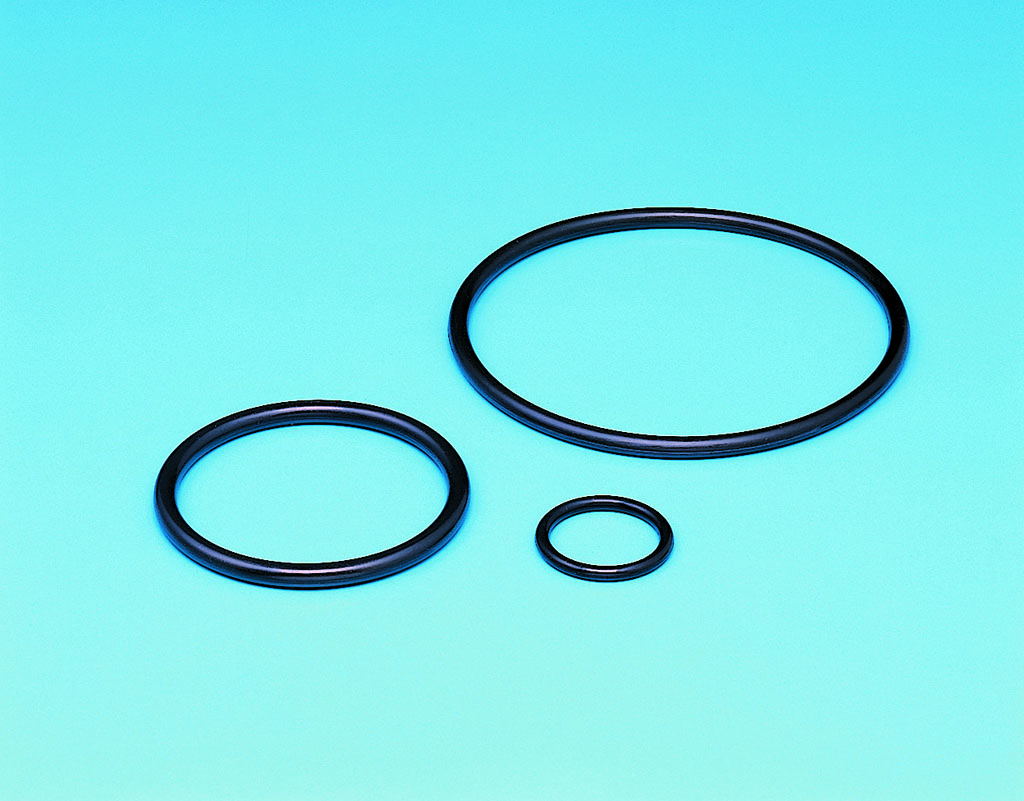

2675-A Rubber O-Ring BLAZER™ O-Ring A

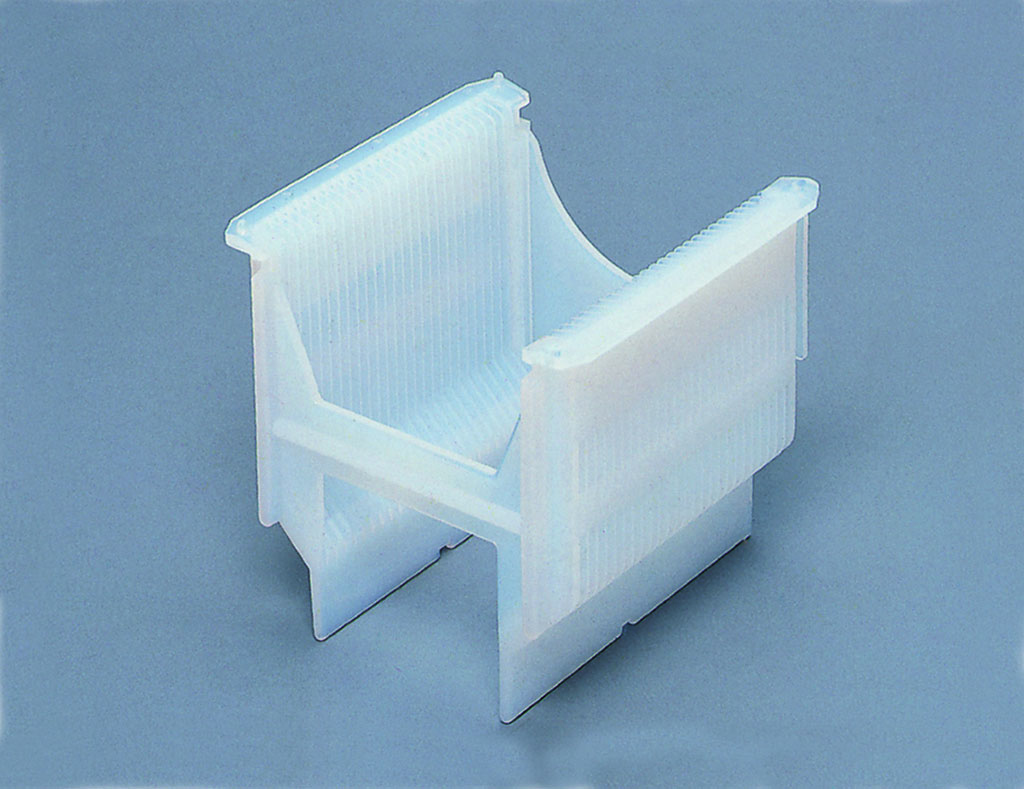

Rubber O-rings for wet processes used for semiconductor and FPD leaning equipment, coaters and developers (coating, development equipment), wet etching systems, filters and other applications. With high chemical resistance and low metal elution to chemical liquids, these O-rings are commonly used as sealing materials in chemical liquid lines.NAFLON™ PFA Wafer Carrier

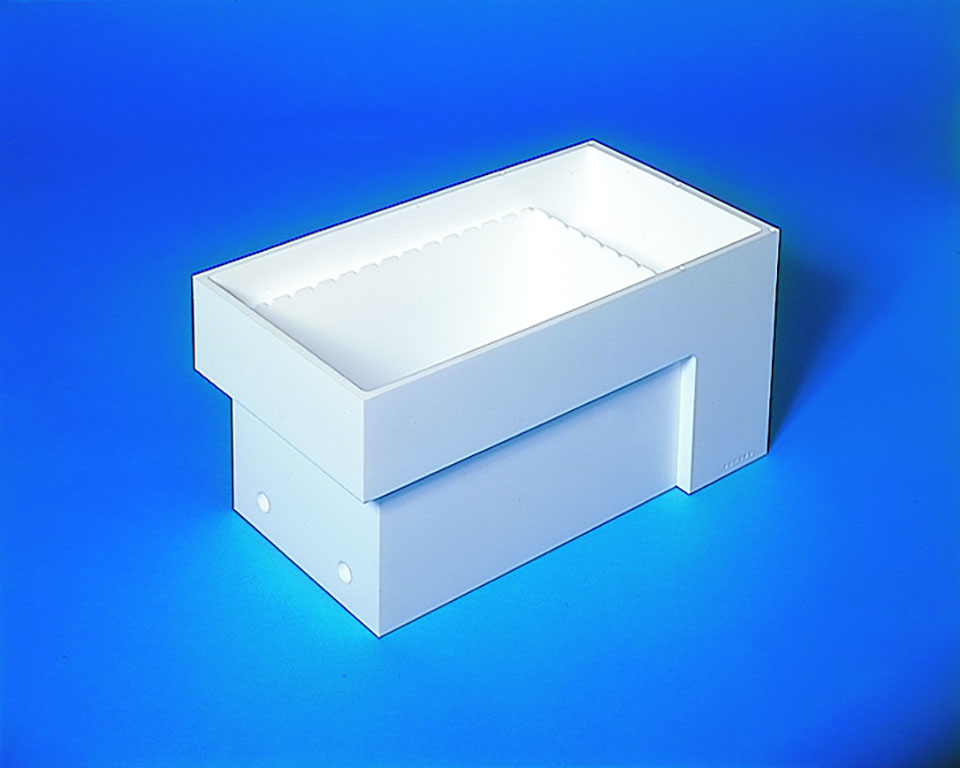

Carrier for water treatment and transportation in cleaning equipment for semiconductor productions9500-M, 9500-H NAFLON™ PFTE Sink

Chemical solution tank used for cleaning wafers in cleaning equipment for semiconductor and FPD production. Since the tank is moulded from PTFE, it is perfect for storing high-purity chemicals and waste liquids.2670-PFW Rubber O-Ring Perfluoro PFW

Rubber O-rings for dry processes used for plasma etching systems and plasma CVD systems in semiconductor and FPD production. With excellent plasma resistance, these O-rings are used as sealing materials in plasma treatment equipment.

* TOMBO is a registered trademark or trademark of NICHIAS Corporation.

* Name of products with "™" are trademarks of NICHIAS Corporation.

* Name of products with "™" are trademarks of NICHIAS Corporation.

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image

Enlarge image