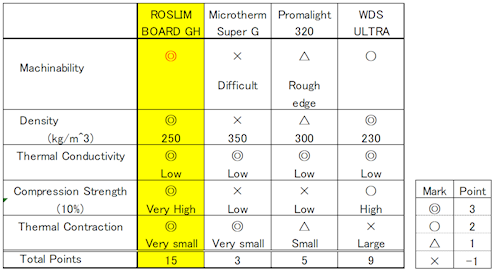

ROSLIM™ comparison

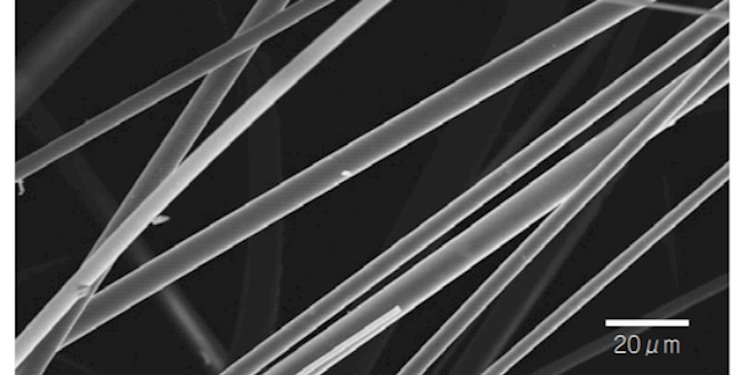

Microporous insulation is one of the best insulation materials on the market used for thermal management and fire protection. The reason is its lower than still air thermal conductivity. The nano-porous structure of the material traps very small air pockets separated within the block structure by a low thermal conducting matrix – thereby creating a very good thermal insulator. This method of manufacturing achieves a highly efficient thermal management solutions. When this solution is applied in a thermal management system, it can improve its overall efficiency as well. In many cases, it is used in combination with other thermal insulation products.

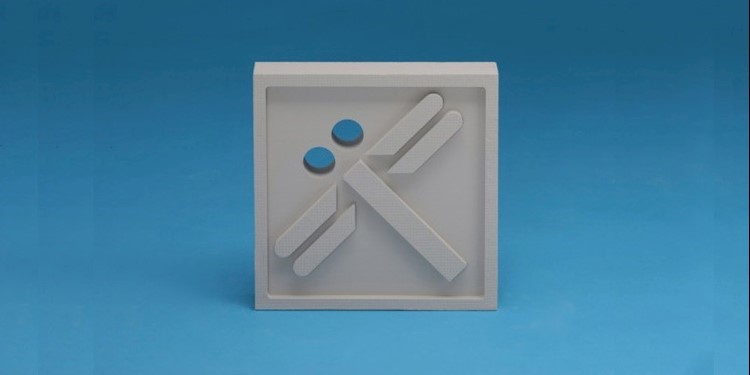

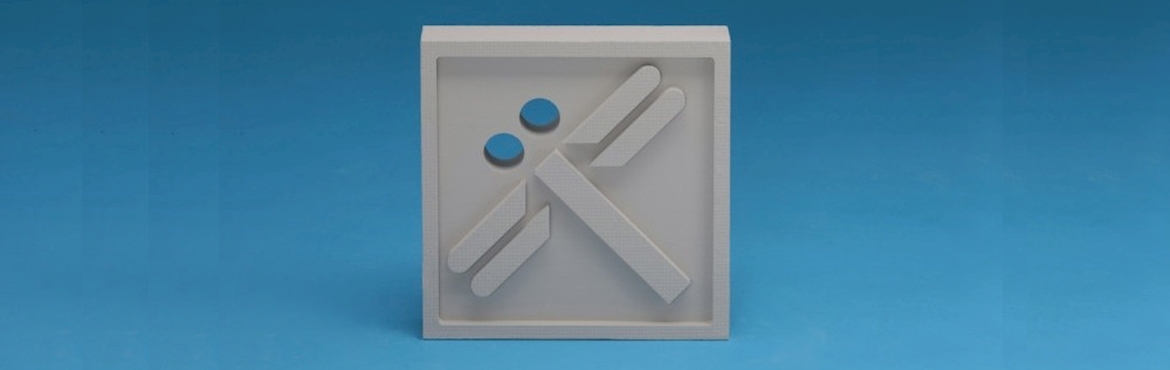

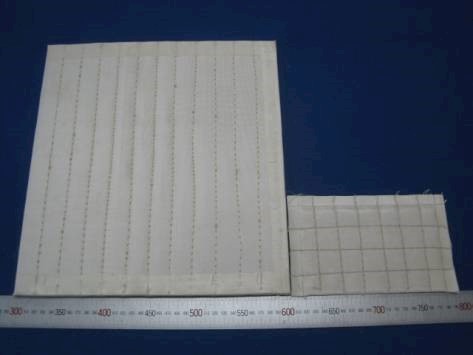

Currently, the most well-known products on the market are Microtherm®, Promalight® and WDS® available in various shapes such as boards (covered or quilted), tubes, and others. It is a common practice to encapsulate microporous insulation due to its tendency to release dust when handled or machined – which can limit the products use (see photographs of such products in Fig 1).

Figure 1 – competitors encapsulated Microporous insulation boards

ROSLIM™ GH is a microporous insulation widely adopted in Japan. It solves many of the current limitations of competitors’ products with its novel composition. By default, it is provided as an uncovered board. Compared to other products available ROSLIM™ releases much smaller amounts of dust (article link here) – which allows users to more easily machine the Board.

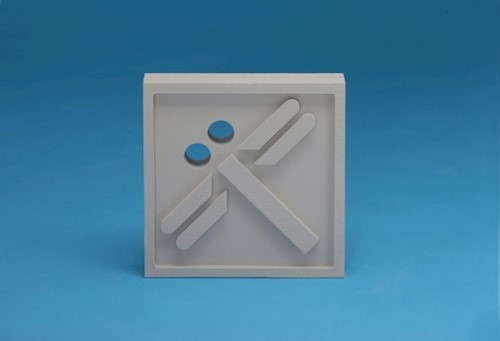

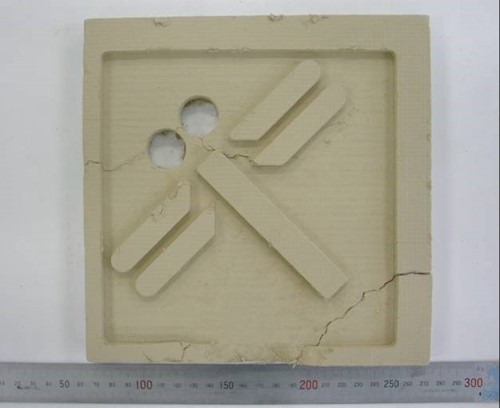

Also, in terms of machinability, ROSLIM™ has been designed to be machinable to high specifications. It can be machined to intricate and compact designs such as those utilized for fuel cells, or compact metrology equipment. Figure 2 demonstrates the excellent machinability of ROSLIM™ GH (LHS photo) vs competitors microporous insulation board (RHS photo).

Figure 2 ROSLIM™ GH (left hand side photo) vs competitors machined microporous insulation board (right had side photo)

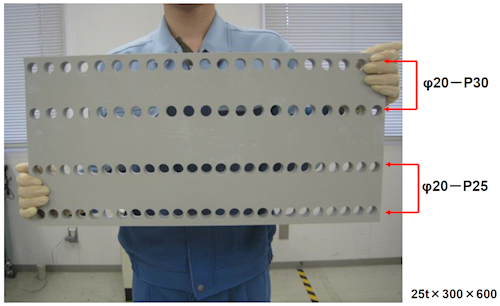

Figure 3 – a 300mm wide x 600 mm length x 25mm thick ROSLIM™ board machined with 2 rows of 21 holes and 2 rows of 25 holes drilled.

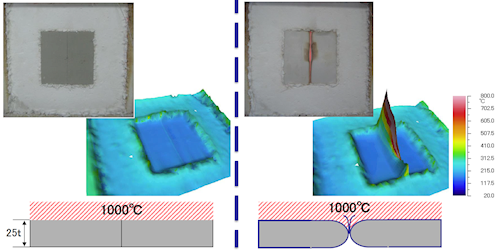

When machining competitor’s microporous insulation products, finished machined parts can be imprecise due to material crumbling, leaving rough edges and corners that can cause heat leakages. Thanks to its composition, NICHIAS ROSLIM™ allows precise corners and edges to be cut – cut parts can be more precisely assembled resulting in the insulation performance of the whole system being uncompromised (see Fig 4).

Figure 4 Insulation performance of a machined and assembled board. ROSLIM™ GH (left hand side photo) vs competitors machined microporous insulation board (right had side photo)

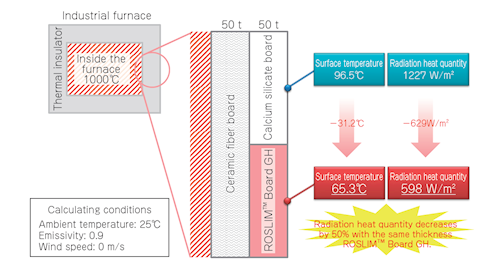

In terms of thermal conductivity, when used as a backup material, ROSLIM™ delivers better performance than the majority of other conventional solutions such as calcium silicate or alumina silicate boards - reducing the number of layers and thickness of insulation required (see Fig 5).

Figure 5 - ROSLIM™ thermal conductivity

A test was conducted at 8000C to compare the thermal conductivity of ROSLIM™ against alumina silicate boards – which resulted in 0.24 W/(m.K) being recorded for alumina silicate board, with ROSLIM™ recording only 0.04 W/(m.K), a 6x lower thermal conductivity, even lower than that of air which was 0.7 W/(m.K).

In summary, physical and performance property benefits of ROSLIM™ are increasingly making ROSLIM™ the product of choice for customers in Japan, elsewhere in Asia and now also in Europe. Thanks to these properties, use of ROSLIM™ can reduce costs by reducing the thickness of the overall insulation system, providing a sought-out option for complex designs, whilst providing reliable insulation performance.

If you have a challenging application that needs an adaptable insulation, feel free to talk to us about ROSLIM™ GH.