ROSLIM™ in Furnaces

Microporous insulation is often selected as a component in a layered thermal insulation system used in heavy duty furnaces to reduce the external skin temperature to approximately 50°C, whilst the internal furnace temperature can be as high as 1,600°C. Examples include carburizing or nitrogenation furnaces, or heating objects like shafts, gears and cam for power transmission.

In recent years, furnace manufacturers have been working to make their furnaces more compact. This means they have had to find alternative solutions that provide the same level of insulation whilst minimizing the overall thickness.

In Japan ROSLIM™ has become the material of choice for its low thermal conductivity (0.04 W/mk at 800°C). It has been selected for use in molten metal furnaces as a backup material, placed behind the insulation that directly faces the molten metal.

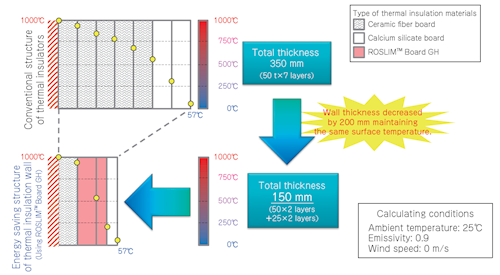

Thanks to its excellent thermal conductivity properties, use of ROSLIM™ can deliver a -50% reduction in the overall insulation thickness of the furnace walls (see figure 1).

Figure 1 – Insulation thickness reduction with ROSLIM™ boards

When combining ROSLIM™ boards with other insulation materials, the overall thickness decreases whilst maintaining the temperature profile of 1,000°C on the furnace interior to 57°C on the exterior whilst also reducing the number of layers of insulation.

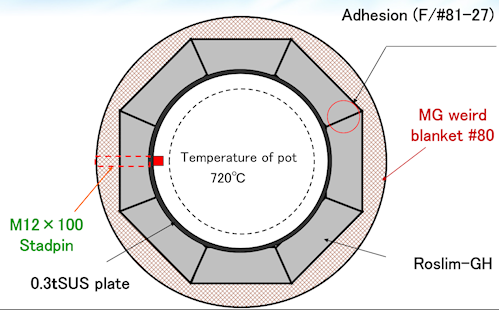

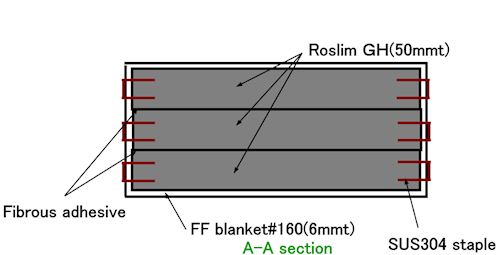

ROSLIM™ is also used in molten pots (figure 2), or as a block unit (figure 3).

Figure 2 - Molten pot

Figure 3 - Combined block unit

ROSLIM™ can be adapted for use in some of the most demanding thermal insulation applications in the industry. If your application requires a solution that can reduce the overall thickness of the system, remain reliable at high temperatures and further lower system costs, than feel free to contact us to discuss your particular application.

ROSLIM™ comparison against other microporous insulation products in the industry.

Read more