Ozone removal filter series Part 2. - Surface treatment application

<Surface treatment application>

Select manufacturing equipment has been known to produce ozone levels during usage. To maintain safe operation, these levels need to be controlled with Ozone filters.

This is specifically relevant to plastic resin surface treatment. When the plastic resin surface is treated with corona for roughness to help adhesion, high voltage comes into contact with oxygen. This process can generate quantities of ozone which are harmful to people.

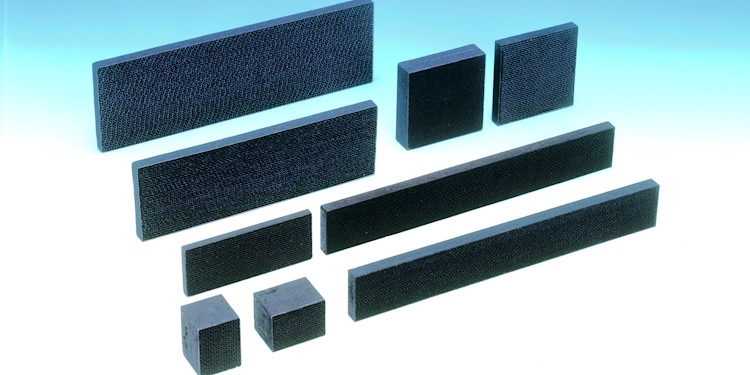

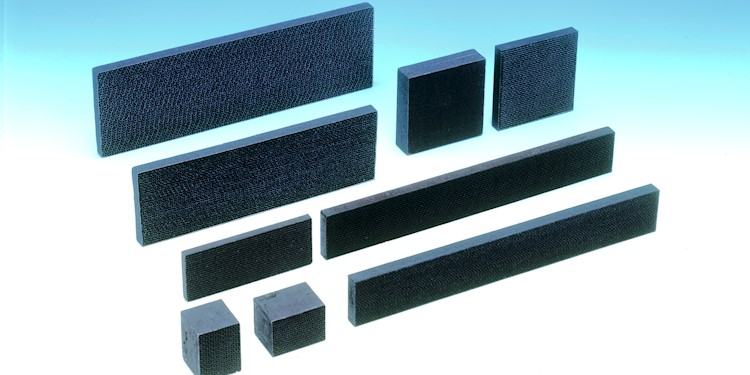

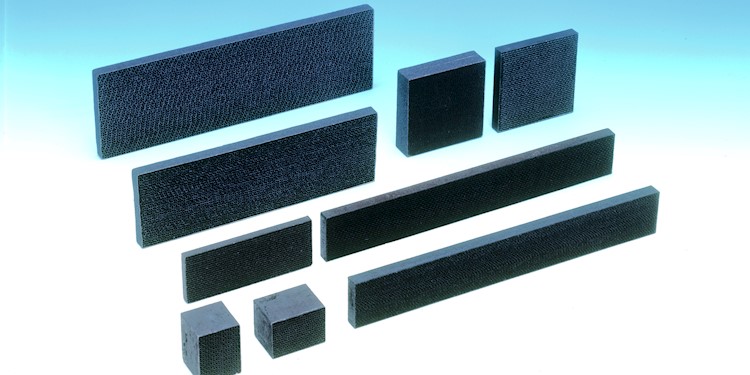

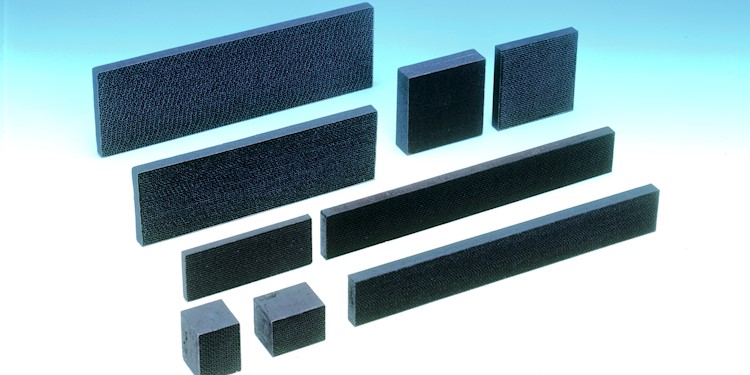

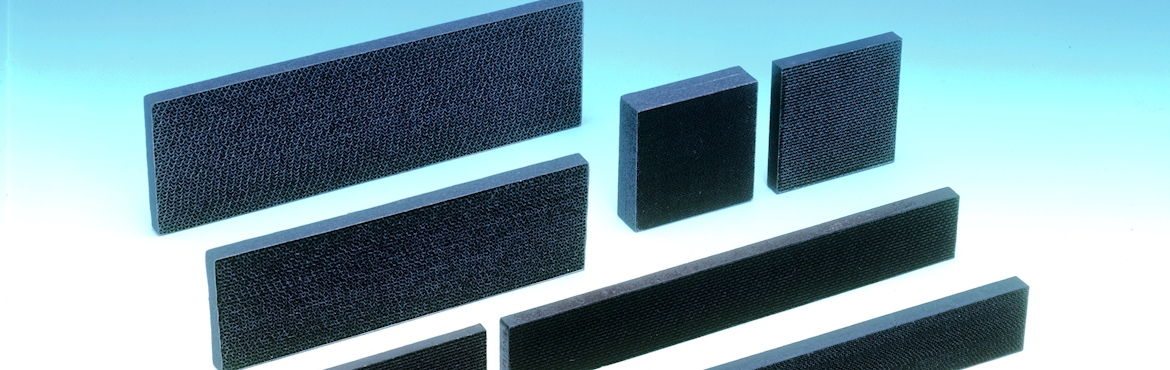

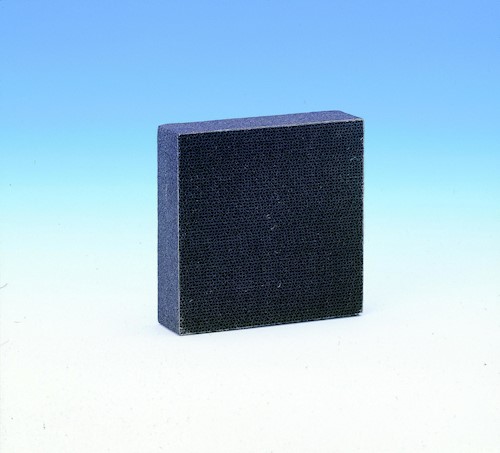

Companies often opt to use a honeycomb type removal filter with an ozone decomposing catalyst to control the ozone emission. This assures that ozone levels are maintained at levels that pose no danger.

NICHIAS has been supplying ozone removal filters for this application with expertise. Hence, for more information on this application and if an ozone removal filter is a right choice for your project, you can contact us at info@nichias.eu or by using the form at the bottom of the page.

In part 3, we will look at the final application of concern where the ozone emissions also need to be managed - copier machine and laser printers.

Ozone removal filters are used in multiple industries and applications. This article focuses on the …

Read moreOzone removal filters are used in multiple industries and applications. This article focuses on the …

Read moreOzone can have harmful effects on the human body

Read moreOne of the main aspects that decide ozone removal filter operating conditions is the ozone concentra…

Read more