NICHIAS SOLVENTCLEAN™ – VOC abatement series – Part 1.

<How does it work?>

SOLVENTCLEAN™ is a concentration rotor developed by NICHIAS that removes Volatile Organic Compounds (VOCs) from the exhaust gas in factories and other facilities. VOC abatement systems that use SOLVENTCLEAN™ not only make a positive impact on the environment, they also protect the workers within the facilities they are installed in from serious health risks. As such, VOC systems are crucial in avoiding dangerous situations that could lead to facility shutdown.

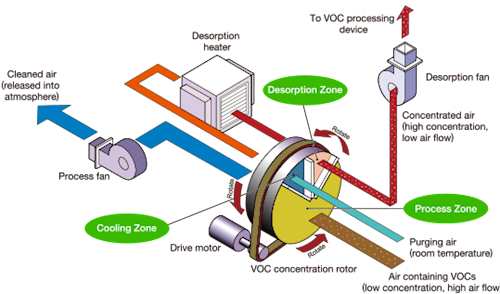

NICHIAS SOLVENTCLEAN™ concentrates small amounts of VOC contained in large volumes of air so that it can be safely processed and disposed of.

First, the VOC laden air is passed through the process zone of the SOLVENTCLEAN™ system at a designed temperature (adsorption process). Then the air is heated at high temperatures (desorption process) and concentrated into a smaller quantity of air.

While the VOCs are concentrated, the rotor of the SOLVENTCLEAN™ system is cooled down again to prepare for the absorption process of the exhaust gas.

In this way, SOVENTCLEAN™ works as a cycle consisting of three linked processes: adsorption, desorption and absorption (cooling).

To avoid any dangerous leakage of gases, the SOLVENTCLEAN™ rotor is enclosed in a case called a Magic Box. The Magic Box facilitates tight air control by using specialized sealing materials. This way any danger to the environment, workers, and the facility is prevented.

If you want to know more, visit our NICHIAS SOLVENTCLEAN™ website.

In Part 2, we’ll look at the most common VOCs found in the related industries.