BLAZER™ comparison - Part 2.

O-rings are widely used in a variety of industries. Their required resistance covers anything from chemical to rapid gas decompression and more. As such, there are countless types of O-rings available.

Using patented cross-linking technology, NICHIAS has developed an O-ring series called BLAZER™ for highly specific and high performing applications. These are widely used in Asia but now made available for customers in Europe with highly demanding applications.

These applications can be grouped into 3 main categories – Chemical and/or Plasma; Heat and/or Steam; Rapid Gas Decompression.

Below, our experts describe the heat and/or steam application and how the products on the market today differ.

Heat and Steam resistance

O-rings can be exposed to temperatures of up to 300°C whether in dry or steam conditions – which can risk that the O-ring suffers from melting or cracking.

The most common products for this application are Kalrez™ and Chemraz™ – used in valves, pumps, reaction furnaces, centrifuges, agitators, analyzers, etc.

High temperature is one of the most challenging environments for O-rings since temperature resistance of a material is decided by the cross-linking agent and its activation energy. In response, NICHIAS has developed its own novel cross-linking agent (technical paper link here). This allows BLAZER™ to have service temperatures up to 320°C in steam environment, or 335°C in dry conditions.

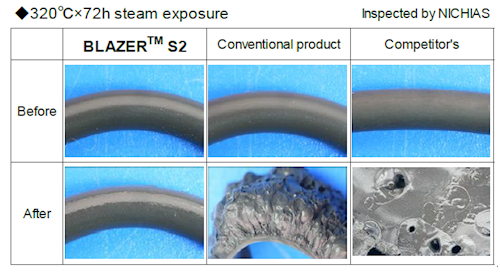

NICHIAS conducted testing at 320°C exposure for 72 hours in steam. NICHIAS BLAZER™ S2 remained unchanged while others at extreme cases ‘sparkled’ or melted, and Steam found a vent through competitors’ products deteriorating the material further and thereby rendering the sealing material unusable.

Results from NICHIAS conducted testing

In addition to withstanding high temperature, the O-ring material of choice must also exhibit the right compression set. The lower the compression set %, the better the O-ring’s resistance to permanent deformation. BLAZER™’s compression rate is comparable to Chemraz™ 555, making the materials almost interchangeable.

Since BLAZER™ can withstand prolonged periods of heat (dry or wet) with a better compression set, it provides users with longer up-time, less frequent maintenance, and lower costs.

But don’t just take our word for it. You can request your sample today to test for yourself.

Comparison chart based on internal test data:

|

|

BLAZER™ |

Kalrez™ |

Chemraz™ |

|

Heat resistance up to 300°C |

✓ |

✘ |

✘ |

|

Steam resistance |

✓ |

✓ |

✓ |

|

Melting |

✓ |

✓ |

✓ |

|

Compression set |

✓ |

n/a |

✓ |

|

Crack resistance |

✓ |

n/a |

✓ |

Applicable BLAZER™ products:

TOMBO No. – BLAZER™ S2, Next

Appropriate replacement for:

Kalrez™ 0090, 3018, 6375

Chemraz™ 526, 555

Difference in performance and applicability of FKM and FFKM material when it comes to plasma resisti…

Read moreImproved EPDM material application as heat exchanger gasket

Read moreNICHIAS Saniclean™ gasket and its use in screw coupling connection

Read moreNICHIAS Saniclean™ gasket and its use in triclamp connection

Read more