New Blazer™ G for RGD application

What if an offshore plant, that produces 250,000 barrels a day, suffers a major breakdown due to a seal failure and must go into an unplanned maintenance shutdown? What if the issue could have been prevented by using the right sealing solution?

Downstream and upstream processes are susceptible to Rapid Gas Decompression (RGD). So, the Oil & Gas industry relies 100% on the gasket’s resistance to RGD to avoid leakages, emergency shutdowns and ultimately higher costs for the plant but also for consumers. A gasket failure due to RGD is simply unacceptable.

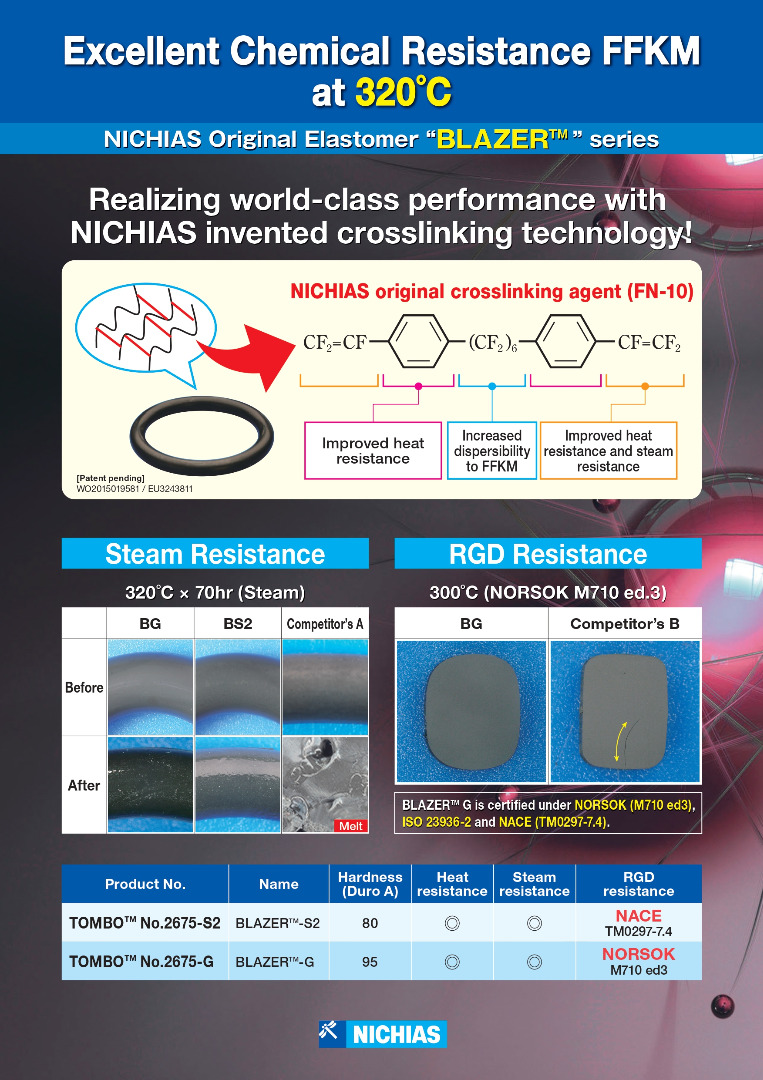

NICHIAS Blazer™ G is an RGD resistant gasket for the Oil & Gas application. It was tested and certified under NORSOK M710 Rev. 3 where all provided samples passed the test conditions.

Along with its chemical resistance relevant to the industry, this gasket was especially developed and manufactured for RGD applications. Along with NORSOK certification, this assures NICHIAS Blazer™ G’s suitability and reliability when used in RGD environments. It is the right sealing solution to avoid leakages and breakdowns caused by Rapid Gas Decompression situations.

If you’d like to know more, feel free to reach out to us through the form below.

Other things you may not know?

SANICLEAN™ is a sanitary tri-clamp EPDM rubber gasket with PTFE outer coating - bonded together as o…

Read moreROSLIM Board GH is Nichias's newest high-temperature microporous insulation board - a product which …

Read moreChemical, ozone and plasma resistant, high-performance o-ring suitable for harsh environments, i.e. …

Read more